Offering a comprehensive selection of high-quality industrial supplies to meet your business needs. Count on us for reliable products that keep your operations running smoothly and efficiently.

The Source For Industrial Supplies

Offering a comprehensive selection of high-quality industrial supplies to meet your business needs. Count on us for reliable products that keep your operations running smoothly and efficiently.

Your Partner in Precision, Supplies, and Service Excellence

With a commitment to quality and accuracy, we provide a full range of industrial supplies, precision calibration, and dependable services. Trust us to support your business with the expertise and resources needed for reliable performance

Who we are

Established Since 1998

A national leader in the supply of Test and Measurement Equipment, Calibration and Training. Providing customers with cost-effective solutions and exceptional customer service.

Global Industry Supplier

Servicing all sectors in all regions, from Utilities, Education and Facilities to Medical, Marine/Offshore and Public Sector. We really can cater for all organisations in all shapes and sizes.

Quality

General Const Lab Calibration is ISO/IEC 17025 accredited through EIAC. We can perform on-site or in-lab calibration services on a wide variety of measurement equipment.

Featured Brands

Calibration Capabilities

Products

Low Prices on Pneumatic tools

Unbeatable prices on power tools and equipment you need around the home.

Norbar Precision, Performance

Unbeatable deals on high-quality torque tools, guaranteed.

Services

Blog

Jan

ISO/IEC 17025 Calibration in the UAE: Why It Matters and Why It Is Worth the Premium?

In industrial operations, the smallest measurement error can quietly become a costly problem—scrap increases, rework rises, downtime becomes frequent, and audit pressure grows. That is why ISO/IEC 17025 calibration is not a formality. It is a technical assurance system that protects measurement integrity and helps organizations make defensible decisions based on accurate data. For companies across the UAE, choosing the right calibration partner is equally important. General Tech Services has been serving the UAE since 1998, building a trusted name not only in calibration services but also in the supply of industrial instruments and solutions. This long-standing presence matters because calibration is not a one-time transaction—it is an ongoing control process that affects quality, safety, and profitability year after year. What ISO/IEC 17025 Means (In Practical Terms)? ISO/IEC 17025 is the international standard that defines competence requirements for calibration laboratories. In practice, it ensures calibration is performed under a controlled, auditable system with: Traceability to recognized national/international standards Documented measurement uncertainty, so results can be trusted and compared Validated methods and controlled procedures Technically competent personnel and systematic quality controls Reliable, audit-ready certification for customer and regulatory requirements For UAE-based manufacturers, utilities, oil & gas operators, and contractors, this is what turns calibration into a measurable business advantage rather than a compliance burden. Why ISO/IEC 17025 Calibration Helps UAE Businesses Across Industries? Oil & Gas, Petrochemicals, and Energy Measurements drive safety and efficiency—pressure, temperature, flow, vibration, and gas detection all influence critical decisions. Impact of 17025 calibration: Fewer process deviations due to sensor drift Improved shutdown/turnaround readiness with defensible records Reduced HSE risk caused by inaccurate readings Manufacturing, Fabrication, and Industrial Automation In production environments, measurement errors multiply into rejects and rework. Impact of 17025 calibration: Improved first-pass yield and reduced scrap More reliable inspection and acceptance decisions Stronger process capability and stable quality KPIs Utilities, Facilities Management, and Building Services Accurate instrumentation supports monitoring, performance, and compliance. Impact of 17025 calibration: Better reliability for control systems and energy management Reduced failures caused by undetected drift Stronger documentation for ISO audits and client inspections Pharmaceuticals, Food, and Laboratories Audit readiness and traceability are non-negotiable. Temperature, humidity, and critical measurements must be defensible. Impact of 17025 calibration: Reduced batch risk and fewer deviations Clear traceability and uncertainty reporting for audits Higher confidence in lab and production results Aviation, Defense, and Precision Engineering Tight tolerances demand stable and credible measurement systems. Impact of 17025 calibration: Consistent inspection outcomes and fewer nonconformities Stronger supplier qualification and quality traceability Why Paying a Premium for Quality Calibration Saves Money? It is common to compare calibration providers by price. However, calibration is a technical risk-control service—cost should be evaluated based on total business impact, not the invoice value. Short-Term Savings (Immediate, Measurable Benefits) 1) Reduced scrap and reworkAccurate instruments prevent bad acceptance/rejection decisions and reduce process variation. 2) Less downtime and fewer instrument-related stoppagesReliable calibration helps maintenance teams identify drift early and plan corrective action proactively. 3) Faster audits and fewer nonconformitiesClear, traceable certificates reduce audit time and eliminate documentation gaps. 4) Better operational decision-makingWhen uncertainty is properly reported, QC and engineering teams can make confident decisions—especially for tight tolerances. Long-Term Savings (Strategic Value) 1) Lower warranty claims and customer rejectionsMany recurring failures trace back to unreliable measurement systems. 2) Better asset life-cycle managementConsistent calibration history supports trending and replacement planning. 3) Reduced compliance and contractual riskWhen disputes occur, defensible measurement records protect your organization. 4) Stronger continuous improvement resultsLean and Six Sigma programs depend on accurate measurement data. Without it, KPI improvements can be misleading. The Hidden Cost of Low-Quality Calibration Low-cost calibration often results in: Weak traceability documentation Unclear or missing uncertainty reporting Inconsistent methods across technicians or sites Certificates that fail customer or regulatory audit expectations Limited guidance when instruments are found out-of-tolerance The real cost is rarely the calibration fee—it is the downstream impact of decisions made using unreliable measurements.

Admin

Dec

Comprehensive VFD, HMI, Instrumentation & Automation Repairs by General Tech Services- Reliable, Experienced, and Backed by Warranty

Industrial Repair Services in the UAE – Reliable, Experienced, and Backed by Warranty Across the UAE’s industrial sector, downtime is one of the biggest challenges companies face. When a key piece of equipment fails—whether it’s a drive, an HMI, or a critical instrument—the impact is immediate. Production slows down, safety margins shrink, and costs start adding up. To help businesses avoid extended downtime and unnecessary equipment replacement costs, General Tech Services offers a full suite of professional repair services for automation, electrical, and industrial control equipment. Every repair is backed by a service warranty, giving customers complete confidence in performance and reliability. VFD Repair Services – Keeping Motors and Production Lines Running Variable Frequency Drives (VFDs) are the heart of most industrial motor systems. Because of heat, dust, electrical fluctuations, and demanding operating environments, drives can fail over time. Our repair team handles everything from small HVAC drives to large industrial units used in pumps, compressors, conveyors, and process machinery. Typical VFD faults we address include: Overvoltage and undervoltage errors Power module and IGBT failures Burnt components or short circuits Control board and communication faults Capacitor failures Overheating and cooling fan issues Brands commonly repaired: Control Techniques, Emerson, ABB, Danfoss, Siemens, Schneider, Mitsubishi, Yaskawa, Omron, Allen-Bradley, Delta, Fuji, and others. What customers can expect: Thorough diagnostics and root-cause analysis Component-level repair instead of costly replacements Load testing to simulate real operating conditions A service warranty after repair Fast turnaround to reduce downtime HMI Repair Services – Restoring Your Operator Interface An HMI malfunction can bring an entire machine—or even an entire production line—to a standstill. We repair HMIs used in industrial automation, packaging, utilities, and manufacturing, ensuring that operators regain full visibility and control as quickly as possible. Common HMI issues we repair: Cracked or unresponsive touchscreens Damaged LCD or backlight Faulty communication ports Software or firmware issues Power supply board failures Non-responsive keypads or dead displays Brands we work with include: Omron, Siemens, Allen-Bradley, Weintek, Schneider, Advantech, Delta, Mitsubishi, Beijer, Wago, IFM, and similar panels used across UAE industries. Our HMI repair approach: Screen and touch panel replacement Calibration and testing under operating conditions Firmware restoration when required Warranty on all completed repairs Instrumentation & Calibration Equipment Repairs Many companies rely on sensitive measurement tools—pressure gauges, flow meters, torque devices, dimensional instruments, data loggers, and more. These tools must stay accurate and reliable, especially in industries where quality control is critical. We repair instruments from brands such as Mitutoyo, Mark-10, WIKA, IFM, Emerson, Honeywell, Jumo, Apera, Dwyer, and several others used throughout the UAE. Our process includes diagnostics, component replacement where needed, and a verification or calibration check to ensure the equipment performs as required. Electronic PCB & Power Supply Repairs For customers looking to extend the life of control systems, our electronics division handles board-level and module-level repairs, including: Power supply units PLC IO boards Control boards Servo drive boards Industrial communication modules Instead of replacing entire units, repairing individual boards can reduce costs significantly while keeping systems running smoothly. Servo Motor Repairs Servo motors are essential in CNC machines, robotics, and high-precision automation lines. We support: Bearing replacement Encoder servicing Stator rewinding Brake assembly repair Cleaning, alignment, and balancing All motors undergo detailed inspection and testing before return. PLC, IO and Automation Module Repairs Automation systems rely heavily on PLCs, IO cards, and communication modules. We repair components used in production plants, utilities, manufacturing lines, HVAC systems, and process industries. We work on modules from leading brands such as Siemens, Omron, Allen-Bradley, Schneider, Wago, and IFM. Why Companies in the UAE Prefer General Tech Services? Experienced technical team Our engineers bring extensive experience across industrial automation, instrumentation, and electrical systems. Transparent repair process Every repair comes with an inspection report detailing the issue and the work carried out. Cost savings Repairs often cost far less than buying new equipment—especially for imported items or discontinued models. Short turnaround times We understand how critical uptime is in UAE industries, so repairs are prioritised accordingly. Warranty-backed repairs Every completed repair is supported by a service warranty for peace of mind. Industry coverage We support companies in oil & gas, manufacturing, utilities, water treatment, aviation, logistics, metal fabrication, and engineering services. Your Trusted Repair Partner in the UAE Whether you need support for a single drive, an entire control panel, or a variety of industrial instruments, our repair team is ready to help. With reliable service, technical expertise, and warranty-backed work, General Tech Services remains a trusted partner for industrial repair needs across the UAE.

Admin

Nov

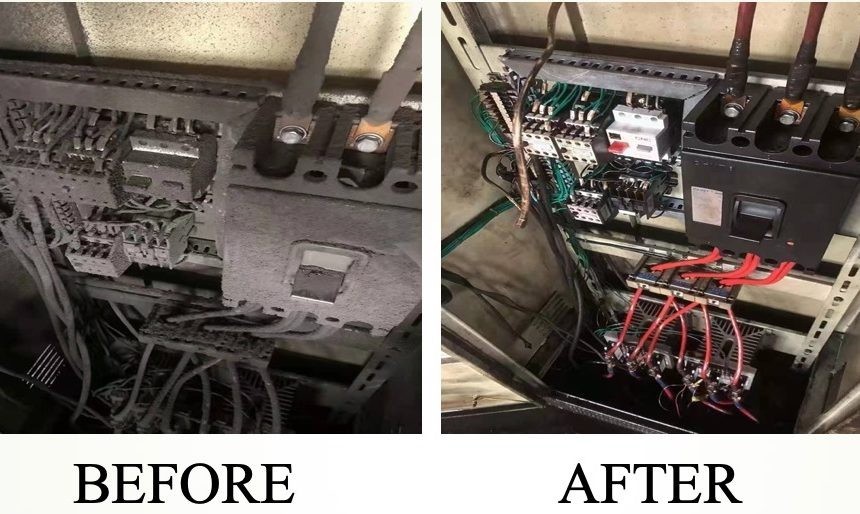

Live Panel Cleaning in UAE: The Future of Preventive Electrical Maintenance

What is Live Panel Cleaning? Live Panel Cleaning is a specialized maintenance process that allows electrical panels, switchgear, and control cabinets to be cleaned while they remain energized. Instead of shutting down your system, trained professionals use non-conductive cleaning methods to safely remove dust, oil, moisture, and contaminants from live electrical components. This process has been used globally for over 20 years and has proven to be one of the safest and most effective preventive maintenance techniques for industries that demand continuous operation. Why Live Panel Cleaning is Vital in the UAE ? The UAE’s harsh desert environment creates unique challenges for electrical systems. Constant exposure to dust, humidity, salt air, and high temperatures accelerates contamination inside panels. Over time, this buildup causes overheating, insulation failure, short circuits, and even fires. Live Panel Cleaning eliminates these risks without interrupting power supply, making it an ideal maintenance solution for: Industrial plants with 24/7 production lines Oil & gas facilities with critical electrical systems Data centres that demand zero downtime Commercial buildings and high-rises with centralized power systems Utilities, airports, ports, and metro networks By cleaning panels while they remain operational, General Tech Services helps UAE industries maintain efficiency, safety, and compliance without sacrificing uptime. Top Benefits for Customers 1. Minimise downtime & protect availability If a panel or switchboard must be de-energised for cleaning, the cost (lost production, HVAC, process delays) can be substantial. Live panel cleaning eliminates or dramatically reduces this downtime, ensuring business continuity. 2. Improve reliability & reduce failures Dust, dirt, oil and moisture degrade insulation resistance, raise temperatures and increase the risk of internal arcing or short-circuit events. Clean equipment runs cooler, safer and longer. For example, one document shows that cleaning live panels reduced internal temperatures and contamination levels significantly. Scribd 3. Extend asset lifespan By removing corrosive deposits and insulating contamination, the cleaning helps prevent premature ageing of components, busbars, contacts, insulation systems and panels themselves — delivering long-term savings. 4. Maintain optimal performance Hot spots, reduced airflow, degraded insulation all degrade efficiency (more heat loss, less effective cooling). Clean panels help maintain performance at peak specification. 5. Cost savings in maintenance & remedial work Instead of reactive repair or shutdowns to fix faults caused by contamination, live cleaning is a proactive strategy. That means lower unplanned maintenance costs and fewer emergency call-outs. 6. Safety compliance & insurance-friendly In high-value installations, insurers and safety audits increasingly expect preventive maintenance regimes. A clean, well-maintained panel setup reduces risk of fire or arc fault damage, which helps with safety ratings and insurance premiums. Industry Applications in the UAE Oil & Gas and Petrochemicals Continuous production environments benefit from non-stop cleaning of MCCs and switchboards. It minimizes risk in explosive or dust-prone zones. Data Centres and IT Facilities Dust can affect sensitive electronic circuits and cooling systems. Live cleaning maintains reliability, ensuring compliance with strict uptime SLAs. Manufacturing and Process Plants Factories operating 24/7 can’t afford shutdowns. Live panel cleaning ensures uninterrupted production and safety compliance. Utilities and Power Distribution Electrical substations and switchgear in coastal or desert areas remain protected from corrosion and environmental contamination. Commercial and Hospitality Buildings For hotels, malls, and skyscrapers, clean electrical systems mean better fire safety, reliability, and operational continuity. Why Choose General Tech Services ? Scheduling flexibility: live cleaning means less disruption, so your operation stays running. Full documentation of before/after contamination levels, temperature changes, insulation resistance improvements — helps with compliance and reporting. Tailored maintenance contracts by industry segment (oil & gas, data centre, manufacturing, utilities) recognising their unique environment and risk profile. Preventive maintenance mindset: positioned not just as a cleaning service, but as an asset protection solution — extending equipment life, reducing failures, and improving safety.

Admin